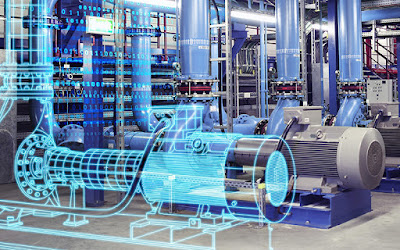

The increasing requirement for the knowledge-based manufacturing and linked supply chains, which are attained with the developed control, sensing, simulations abilities, modeling, and several others are fueling the growth of the smart manufacturing market. Additionally, the smart manufacturing market is estimated to enlarge at a compound annual growth rate (CAGR) of 15.75% during the 2018-2023 periods. The requirement for the data-driven decision making, intense price competition, and streamlining of manufacturing developments for higher productivity are the key fostering forces of this market. Therefore, the players in the industry are actively looking for methods to deduct the price and generate the manufacturing agile, efficient, accelerated and compliant with customer product quality. The smart manufacturing not only fulfills such requirements but also offers additional advantages name as real-time optimization and dynamic production, in turn booming the requirement for smart manufacturing at a speedy rate.

Furthermore, the requirement for the development and modernization of the legacy control systems has become necessary to compete at an international standard, which has also boom up the efforts for the digitations and IT & OT convergence. As a result, the digital plants and developed manufacturing technologies are set to develop the factories, production centers, corporate, and entire value chains, thereby fueling the fourth industrial revolution.

According to the report analysis, ‘Industry 4.0: Global Smart Manufacturing Market (2018 - 2023)’ states that in the global smart manufacturing market, there are numerous key players which are presently functioning more positively for leading the fastest market growth and dominating the high value of market share during the short a span of time and more positively while employing the skilled workers, setting more developed and advanced technologies, investing the handsome value in the several developments and establishing more research and development programs includes KUKA, ABB Ltd, Cisco Systems, Inc., IBM Security, The Raytheon Company, Stratasys, Ltd., The Emerson Electric Co., Alpine Data Labs, SAP SE, Maersk and several others.

Additionally, based on the end-user, the highest implementation of smart manufacturing is likely in the aerospace sector, which will increase at a CAGR of 25% during the calculated period. This is driven by the augmented production of advanced aircraft, such as the Boeing 787 and Airbus A350. Improved usage of the robots in the industrial control mechanisms will fuel the automotive and industrial equipment end users sector, at CAGRs of 15.6% and 11.2% respectively, during the 2018-2023 period. The chemicals and materials, food and agriculture, and healthcare segmented are also approximately of the auspicious areas for the employment of smart manufacturing technologies.

Although, based on the regional analysis, North America is the foremost region to do innovation in the smart manufacturing market and occupied almost 27% of the global market in 2017. Massive reserves in the smart manufacturing technologies, tax subsidies for manufacturers, and originations in robotics have propelled the growth of the smart manufacturing market in the country. The Asia-Pacific, experiencing high industrialization, engaged a 25% share in 2017. The Latin America and the Middle East and Africa markets though, still at promising stages, are undergoing decent growth. Hence, in the near years, it is anticipated that the entire market of smart manufacturing will increase around the globe more significantly over the forecasted period.

Companies covered:-

KUKA

ABB Ltd

Cisco Systems, Inc.

IBM Security

The Raytheon Company

Stratasys, Ltd.

The Emerson Electric Co

Alpine Data Labs

SAP SE

Maersk

To Know More, Click On The Link Below:-

Contact Us:-

Ken Research

Ankur Gupta, Head Marketing & Communications

+91-9015378249